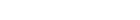

Viscosity Enhancer

- PES 1003 Viscosity Enhancer increases molecular weights of polyesters.

- The reaction rate of Masterset PES 1003 Viscosity Enhancer depends on temperature and the residence time.

- In APET extrusion, sometimes final IV decrease to the levels lower than 0.550 dl/g due to several reprocessing

- This level of IV causes brittleness in APET even at room temperature.

- 0,3 % dosing eliminates brittleness problem

- PES 1003 performs well especially in twin screw extrusion systems

- About Us

-

Services

- Services

- Technology Center

- Research & Test Lab

-

Markets

- Markets

-

Fibers

- Fibers

- UV Stabilizers for Fibers

- Halogen Free Flame Retardant Masterbatch

- Antimicrobial Additives for Fibers

- Mono Color Concentrates for Polyester and Polyamide Fibers

- Atmospheric Dyeability for Polyester Fibers

- IR Absorber for Heat Management in Fibers

- Antiphenolic Yellowing Additive for Polyamide

- Soft Touch Additives for Fibers

- Antistatic Masterbatch for PA6 and PP

- Halogenated Flame Retardant Masterbatch for PP Fibers

- Carpets

- Nonwovens

- Flexible Films

- Thick Sheets

-

Rigid Films

- Rigid Films

- Slip Antiblock Masterbatches

- Process Aid for Monolayer Film

- Antiblock Masterbatch for Printing Applications

- Matting Additive for PET

- UV Content Protection for PET

- Impact Modifier

- Nucleating Agent for CPET

- Color Enhancer Additive for RPET

- Viscosity Enhancer

- White/Black/Color Masterbatches

- Transparent FR for PET Sheet

-

Other Plastics

- Other Plastics

- Molding Process Aid for Injection Applications

- Sustainability