Pinning Masterbatch

- One of the requirements of film grade resin is the melt conductivity level. Specific mixtures of metals, phosphorous levels, and concentration of total ion impurities are the determining factors for melt conductivity.

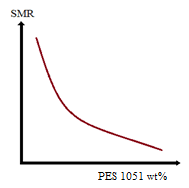

- Masterset PES 1051 contains optimzed mixtures of elements which improves the melt conductivity without increasing crystallization rate. Increasing crystallization rate will increase the waste in the edges of the films.

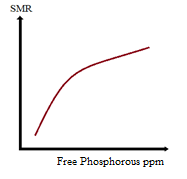

- Increasing the phosphorous level in PET will decrease the melt conductivity whereas decreasing the phosphorous level will increase the melt conductivity. Therefore, free phosphorous level in PET should be well controlled.

- For specific melt resistivity Requirement of 7-15x10⁷ ohms.cm, % 1 dosing is recommended. For this level, for TPA based polymerization process, the phosphorous level should be at the level of 20 ppm max.

- One other factor affecting melt conductivity is the carboxylic acid number. Therefore, the CEG level should be controlled to keep constant melt conductivity.

|

|

- About Us

-

Services

- Services

- Technology Center

- Research & Test Lab

-

Markets

- Markets

-

Fibers

- Fibers

- UV Stabilizers for Fibers

- Halogen Free Flame Retardant Masterbatch

- Antimicrobial Additives for Fibers

- Mono Color Concentrates for Polyester and Polyamide Fibers

- Atmospheric Dyeability for Polyester Fibers

- IR Absorber for Heat Management in Fibers

- Antiphenolic Yellowing Additive for Polyamide

- Soft Touch Additives for Fibers

- Antistatic Masterbatch for PA6 and PP

- Halogenated Flame Retardant Masterbatch for PP Fibers

- Carpets

- Nonwovens

- Flexible Films

- Thick Sheets

-

Rigid Films

- Rigid Films

- Slip Antiblock Masterbatches

- Process Aid for Monolayer Film

- Antiblock Masterbatch for Printing Applications

- Matting Additive for PET

- UV Content Protection for PET

- Impact Modifier

- Nucleating Agent for CPET

- Color Enhancer Additive for RPET

- Viscosity Enhancer

- White/Black/Color Masterbatches

- Transparent FR for PET Sheet

-

Other Plastics

- Other Plastics

- Molding Process Aid for Injection Applications

- Sustainability