Antiblock Masterbatches for BOPET

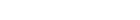

- Setas has unique technology to get excellent silica dispersion. Silica is well dispersed in polyester matrix resulting in excellent filter test value in 14-micron filter

- PES 1024 and PES 1105 AB are proven antiblocks in BOPET films and used regularly by several BOPET film producers

- PES 1024 AB contains 5 wt% (50000 ppm) synthetic silica. PES 1105 AB contains 10 wt% synthetic silica

- The average particle size of the silica is 3.2 micron

Accelerated Filter Pressure Curve for PES 1105 AB (14 mic filter)

Physical and Optical Film Properties of Antiblock Masterbatches

| 1. Physical and Mechanical Properties | %2,7 PES 1024 AB or %1,35 PES 1105 AB (1350 ppm Silica in Final Film) |

%30 Std 4500 ppm Silica Resin (1350 ppm Silica in Final Film) |

||

| KALINLIK (THICKNESS) ASTM D 374 |

12 mic | 12 mic | ||

| YOĞUNLUK (DENSITY) ASTM D 1505 |

1,4 gr/cm³ | 1,4 gr/cm³ | ||

| VERİM (YIELD) ASTM D 4321 |

59,5 m²/kg | 58,4 m²/kg | ||

| GERİLME DİRENCİ (TENSILE STRENGTH) ASTM D 2578 |

MD | 218 N/mm² | 227 N/mm² | |

| TD | 257 N/mm² | 264 N/mm² | ||

| KOPMADA UZAMA (ELONGATION AT BREAK) ASTM D 882 |

MD | 131% | 127% | |

| TD | 89% | 81% | ||

| ELASTİK MODÜL (ELASTIC MODULUS) ASTM D 882 |

MD | 3140 N/mm² | 3012 N/mm² | |

| TD | 3922 N/mm² | 4210 N/mm² | ||

| ISIL ÇEKME (THERMAL SHRINKAGE) ASTM D 2732 |

% | MD | 4,4 | 4,4 |

| TD | 4,2 | 4,2 | ||

| %2,7 PES 1024 AB or %1,35 PES 1105 AB (1350 ppm Silica in Final Film) |

%30 Std 4500 ppm Silica Resin (1350 ppm Silica in Final Film) |

|||

| SÜRTÜNME KATSAYISI (COEFFICIENT OF FRICTION) ASTM D 1894 |

F/Film | TT | 0,43 | 0,63 |

| TN | 0,42 | 0,51 | ||

| NN | 0,36 | 0,49 | ||

| F/Metal | TM | 0,26 | 0,34 | |

| NM | 0,2 | 0,24 | ||

| HAZE (ASTM D1003) | % | 1,5 | 1,4 | |

| PARLAKLIK (GLOSS, 45º) ASTM D 2457 |

T (bright) | 144 | 145 | |

| N (mat) | 145 | 145 | ||

| BLOCKING FORCE ASTM D 3354 |

gf | 20,4 | 19,6 | |

| COLOR (L, a, b) | % | 67,1 / -0,69 / 1,89 | 67,3 / -0,78 / 2,06 | |

| YÜZEY GERİLİMİ (SURFACE TENSION) ASTM D 2578 |

T | 60 dyn/cm | 60 dyn/cm | |

| N | 46 dyn/cm | 46 dyn/cm | ||

- About Us

-

Services

- Services

- Technology Center

- Research & Test Lab

-

Markets

- Markets

-

Fibers

- Fibers

- UV Stabilizers for Fibers

- Halogen Free Flame Retardant Masterbatch

- Antimicrobial Additives for Fibers

- Mono Color Concentrates for Polyester and Polyamide Fibers

- Atmospheric Dyeability for Polyester Fibers

- IR Absorber for Heat Management in Fibers

- Antiphenolic Yellowing Additive for Polyamide

- Soft Touch Additives for Fibers

- Antistatic Masterbatch for PA6 and PP

- Halogenated Flame Retardant Masterbatch for PP Fibers

- Carpets

- Nonwovens

- Flexible Films

- Thick Sheets

-

Rigid Films

- Rigid Films

- Slip Antiblock Masterbatches

- Process Aid for Monolayer Film

- Antiblock Masterbatch for Printing Applications

- Matting Additive for PET

- UV Content Protection for PET

- Impact Modifier

- Nucleating Agent for CPET

- Color Enhancer Additive for RPET

- Viscosity Enhancer

- White/Black/Color Masterbatches

- Transparent FR for PET Sheet

-

Other Plastics

- Other Plastics

- Molding Process Aid for Injection Applications

- Sustainability