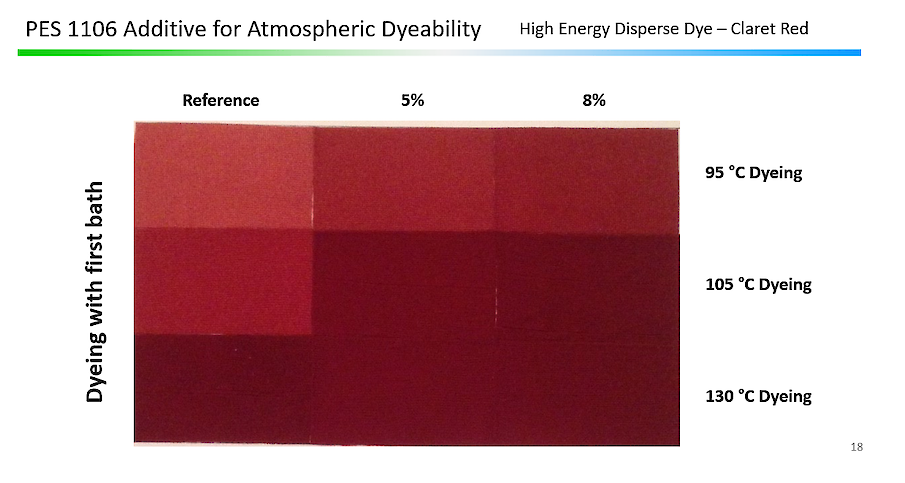

Atmospheric Dyeability for Polyester Fibers

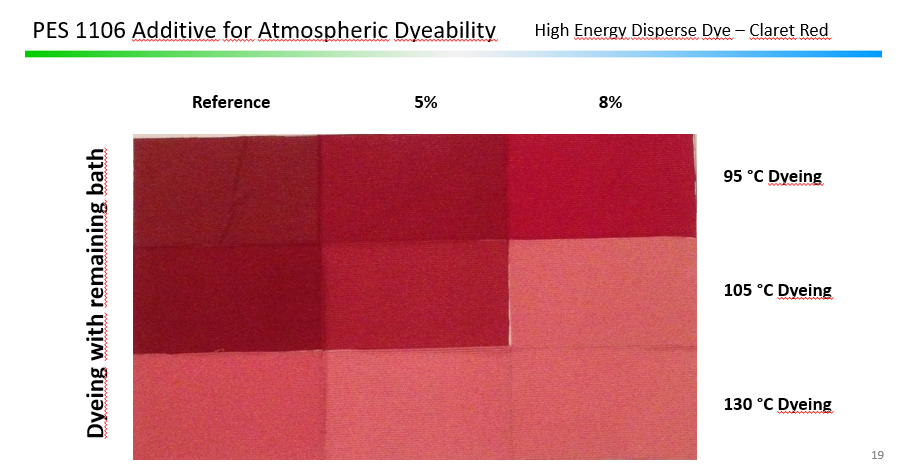

- PES 1106 can be dosed during the spinning of polyester fibers around 5-8 wt% levels

- Supplied in crystalline form and can be dried in dehumidified dryers at 100 C

- It provides dyeability of PET fibers at 95°C – 105 °C and better exhaustion of dyestuff is possible

- Can be used to achieve darker colors once used at standard dyeing temperatures

- For dark colors, up to 20 wt%, less dye can be used to achieve the same target colors at standard dyeing temperatures

- Provides soft hand feel on polyester yarn/fabric

- About Us

-

Services

- Services

- Technology Center

- Research & Test Lab

-

Markets

- Markets

-

Fibers

- Fibers

- UV Stabilizers for Fibers

- Halogen Free Flame Retardant Masterbatch

- Antimicrobial Additives for Fibers

- Mono Color Concentrates for Polyester and Polyamide Fibers

- Atmospheric Dyeability for Polyester Fibers

- IR Absorber for Heat Management in Fibers

- Antiphenolic Yellowing Additive for Polyamide

- Soft Touch Additives for Fibers

- Antistatic Masterbatch for PA6 and PP

- Halogenated Flame Retardant Masterbatch for PP Fibers

- Carpets

- Nonwovens

- Flexible Films

- Thick Sheets

-

Rigid Films

- Rigid Films

- Slip Antiblock Masterbatches

- Process Aid for Monolayer Film

- Antiblock Masterbatch for Printing Applications

- Matting Additive for PET

- UV Content Protection for PET

- Impact Modifier

- Nucleating Agent for CPET

- Color Enhancer Additive for RPET

- Viscosity Enhancer

- White/Black/Color Masterbatches

- Transparent FR for PET Sheet

-

Other Plastics

- Other Plastics

- Molding Process Aid for Injection Applications

- Sustainability