Antiphenolic Yellowing Additive for Polyamide

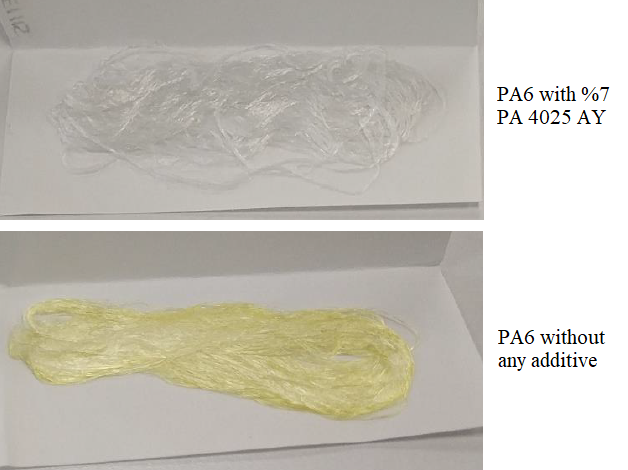

- Setas invented a new technology to eliminate the PA6 fiber treatment process in dye houses to eliminate phenolic yellowing of white socks during storage.

CURRENT PROCESS

PA6 Fiber manufacturers produce PA6 fibers. PA6 fibers are sent to dye houses for surface acidic treatment to eliminate phenolic yellowing and for optically whitening. Sock manufacturers produce socks using these treated fibers.

NEW TECHNOLOGY

During the manufacturing of PA6 fibers, Masterset Antiphenolic yellowing additive containing optical whitener masterbatch is added as masterbatch form. Sock Manufacturers directly use this fiber. Dye houses are eliminated in between. 50 L water/kg fiber is saved.

Fibers After Phenolic Yellowing Test

(ISO 105-X 18:2007)

- About Us

-

Services

- Services

- Technology Center

- Research & Test Lab

-

Markets

- Markets

-

Fibers

- Fibers

- UV Stabilizers for Fibers

- Halogen Free Flame Retardant Masterbatch

- Antimicrobial Additives for Fibers

- Mono Color Concentrates for Polyester and Polyamide Fibers

- Atmospheric Dyeability for Polyester Fibers

- IR Absorber for Heat Management in Fibers

- Antiphenolic Yellowing Additive for Polyamide

- Soft Touch Additives for Fibers

- Antistatic Masterbatch for PA6 and PP

- Halogenated Flame Retardant Masterbatch for PP Fibers

- Carpets

- Nonwovens

- Flexible Films

- Thick Sheets

-

Rigid Films

- Rigid Films

- Slip Antiblock Masterbatches

- Process Aid for Monolayer Film

- Antiblock Masterbatch for Printing Applications

- Matting Additive for PET

- UV Content Protection for PET

- Impact Modifier

- Nucleating Agent for CPET

- Color Enhancer Additive for RPET

- Viscosity Enhancer

- White/Black/Color Masterbatches

- Transparent FR for PET Sheet

-

Other Plastics

- Other Plastics

- Molding Process Aid for Injection Applications

- Sustainability